Introduction: Gallery wrap stretcher bars play a pivotal role in transforming paintings into captivating masterpieces. These unassuming wooden frames provide the structure and support necessary for canvas art to shine. In this article, we delve into the intricate world of gallery wrap stretcher bar manufacturing, exploring the materials used, the process involved, and the impact it has on the final presentation of artwork.

- The Foundation of Excellence: Gallery wrap stretcher bars are meticulously crafted using high-quality materials to ensure the longevity and integrity of the artwork they showcase. The most common wood choices for manufacturing stretcher bars include pine, birch, and poplar. These woods are selected for their durability, resistance to warping, and ability to support the tension of stretched canvases. The manufacturing process begins with carefully cutting and shaping the wood into precise lengths, widths, and depths, taking into account the desired size and weight-bearing capacity of the final stretcher frame.

- The Joining Techniques: The strength and stability of gallery wrap stretcher bars heavily rely on the joining techniques employed during manufacturing. The most common methods include mortise and tenon joints, lap joints, and mitered joints. Mortise and tenon joints involve interlocking pieces of wood, creating a sturdy connection. Lap joints overlap the wood pieces and are often reinforced with screws or staples. Mitered joints, on the other hand, create a clean and seamless corner by cutting the wood at a 45-degree angle. Each joining technique contributes to the overall strength and structural integrity of the stretcher bar.

- Precision Assembly: Once the wood is cut and joined, the next step is the precise assembly of the stretcher bar. Manufacturers use specialized machinery and tools to ensure accuracy in the alignment and measurement of the frame. The corners are squared, and the pieces are secured together using adhesives, nails, or staples, depending on the manufacturing process. Attention to detail is crucial during this stage, as any misalignment or instability in the frame can impact the final appearance of the artwork.

- Quality Control and Finishing Gallery wrap stretcher bars undergo rigorous quality control measures to ensure they meet the highest standards. Each frame is carefully inspected for any imperfections, such as rough edges or uneven surfaces, which could affect the stretching process. Sanding and smoothing techniques are applied to eliminate any irregularities. The frames are then finished with appropriate coatings or sealants to protect the wood from moisture, environmental factors, and to enhance the overall aesthetics. A well-finished stretcher bar provides a clean and professional presentation, highlighting the artwork’s focal point.

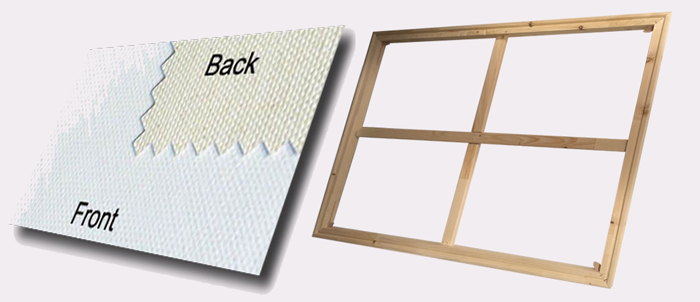

- Supporting the Canvas: Once manufactured, gallery wrap stretcher bars are ready to serve as the foundation for stretched canvas art. Artists carefully position the canvas over the frame, pulling it taut and securing it to the back using staples or specialized canvas pliers. The tightness of the canvas is crucial, as it determines the smoothness and overall appearance of the artwork. Gallery wrap stretcher bars ensure that the canvas remains properly tensioned, preventing sagging or warping over time.

Conclusion: The manufacturing process of gallery wrap stretcher bars combines precision, craftsmanship, and attention to detail to create the perfect canvas for artistic expression. These unobtrusive frames provide a solid foundation, allowing the artwork to take center stage while ensuring its longevity. The careful selection of materials, joining techniques, assembly, and finishing all contribute to a superior gallery wrap stretcher bar that enhances the presentation of artwork, captivating viewers for years to come.